Watch On

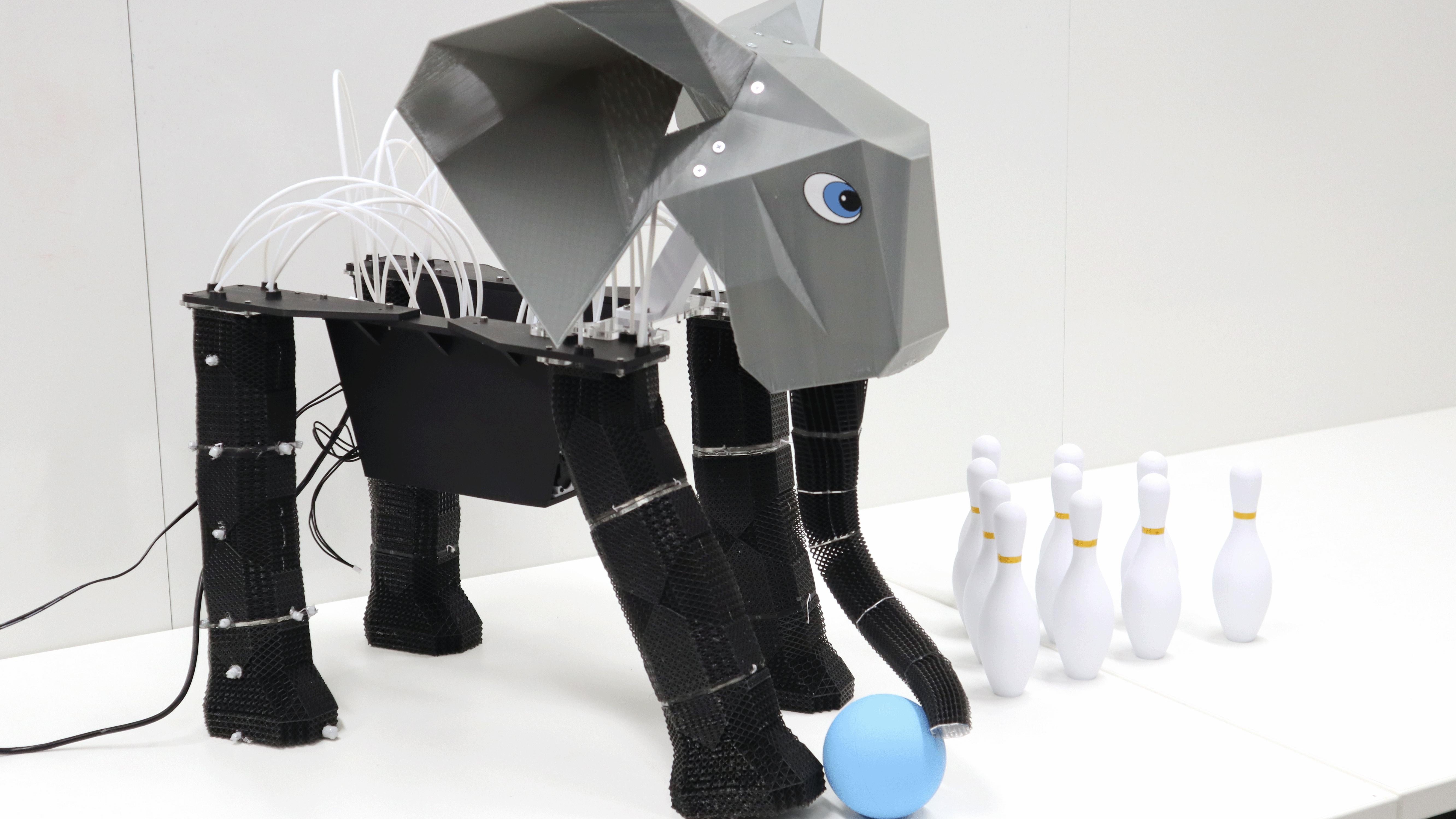

A first-of-its-kind robot elephant can pick flowers and go bowling thanks to 3D-printed technology that mimics biological tissues, according to a new study.

Researchers in Switzerland created a programmable lattice structure that can take on a variety of different forms, giving the robot a flexible synthetic trunk that can handle delicate tasks and rigid bone-like support in its legs for more natural movement.

The researchers demonstrated the benefits of their geometric lattice design by showing the robot elephant delicately grasping a flower with its trunk and kicking a bowling ball. In a video shared by the researchers, the robot elephant kicked a small bowling ball at 10 pins — and managed to knock down seven of them.

The lattice is made from foam and contains many individual units, or cells, that the researchers can program into different shapes and positions. The team claims that their tech can have more than one million different configurations that combine to make “infinite” geometric variations, allowing for the design of lightweight and adaptable robots, according to a new study published Wednesday (July 16) in the journal Science Advances.

“We used our programmable lattice technique to build a musculoskeletal-inspired elephant robot with a soft trunk that can twist, bend and rotate, as well as more rigid hip, knee, and foot joints,” study first author Qinghua Guan, a postdoctoral researcher in the Computational Robot Design and Fabrication Lab at the EPFL university in Switzerland, said in a statement. “This shows that our method offers a scalable solution for designing unprecedentedly lightweight, adaptable robots.”

Related: Intrepid baby-faced robot dons a jetpack for its next adventure — becoming the first humanoid robot to fly

Most robots, including the most advanced humanoid robots, are pretty clunky and awkward in the way that they move compared with humans and other animals. Our varied movement comes from a network of muscles, tendons, ligaments and bones, often all working together, which is a complexity that’s difficult to replicate in robots, according to the statement.

An elephant’s trunk is a particularly complex piece of evolutionary engineering. Each trunk contains around 90,000 bundles of muscle fibers, called muscle fascicles, that allow elephants to use them like a multipurpose tool.

The 3D printed lattice gets its complexity from its individual cell units. These cells have two main geometric shapes that provide different levels of stiffness, deformation and load-bearing properties. Furthermore, researchers can create what are essentially hybrid shapes on a spectrum between the two main shapes, allowing for even more variation, according to the statement.

“This approach enables the continuous spatial blending of stiffness profiles and allows for an infinite range of blended unit cells,” study co-author Benhui Dai, a doctoral student in the lab at EPFL, said in the statement. “It’s particularly suited for replicating the structure of muscular organs like an elephant trunk.”